Enhancing Manufacturing Efficiency with Machine Learning Algorithms

In today’s fast-paced and highly competitive manufacturing sector, enhancing efficiency and productivity is essential for businesses to stay ahead of the game. Machine learning algorithms offer a powerful solution to streamline and optimize manufacturing processes, resulting in improved efficiency, reduced costs, and enhanced profitability. Let’s take a closer look at how machine learning algorithms are transforming the way manufacturing operates.

Machine learning algorithms are a subset of artificial intelligence that enable computers to learn and make predictions without being explicitly programmed. These algorithms are designed to analyze vast amounts of data, identify patterns, and make accurate predictions or decisions based on that data. In the manufacturing industry, machine learning algorithms can be applied to various areas to improve efficiency, such as predictive maintenance, quality control, production planning, and supply chain management.

One significant application of machine learning algorithms in manufacturing is predictive maintenance. Traditional maintenance strategies are often based on fixed schedules or reactively addressing failures when they occur. This approach can lead to unnecessary downtime, high maintenance costs, and inefficient use of resources. By implementing machine learning algorithms, manufacturers can analyze real-time data from sensors and monitoring systems to predict equipment failures or maintenance requirements accurately. This enables proactive maintenance, ensuring that equipment is serviced before failures occur, minimizing downtime, and reducing maintenance costs. For example, algorithm-based predictive maintenance can help manufacturers identify pending faults in a piece of machinery, schedule maintenance during idle periods, and thus avoid unexpected breakdowns in the middle of production.

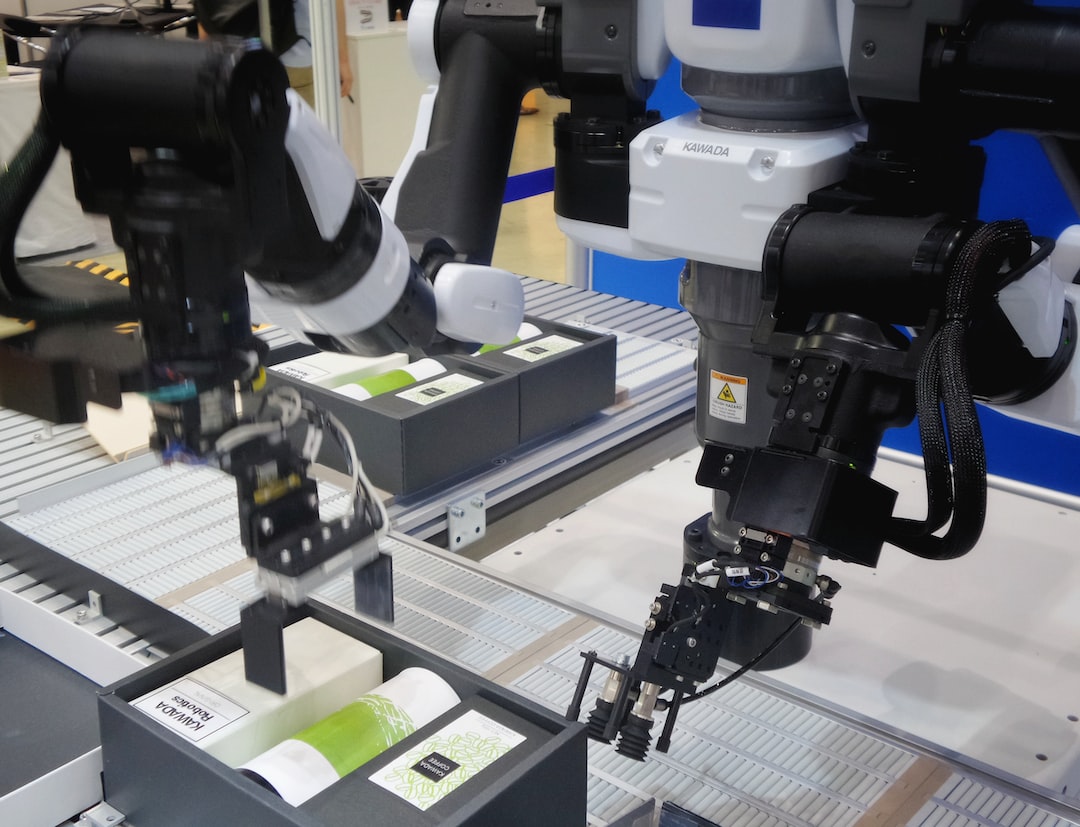

Another area where machine learning algorithms can enhance manufacturing efficiency is in quality control. Ensuring product quality is crucial for manufacturers to maintain their reputation and customer satisfaction. Machine learning algorithms can analyze data from various sources, such as sensors, cameras, and inspection systems to identify defects or anomalies in real-time. This enables manufacturers to detect and address quality issues early on, preventing the production and delivery of defective products. By leveraging machine learning algorithms for quality control, manufacturers can significantly reduce rework, scrap, and warranty costs, resulting in improved product quality and customer satisfaction.

Production planning is another critical aspect of manufacturing that can benefit greatly from machine learning algorithms. Optimizing production planning involves determining the most efficient allocation of resources, such as labor, materials, and machines, to meet production demands while minimizing costs. Machine learning algorithms can analyze historical production data, demand forecasts, and other relevant factors to generate accurate production plans. By considering factors such as machine performance, maintenance requirements, and production bottlenecks, these algorithms can optimize production schedules, reducing idle time and maximizing resource utilization. This results in improved production efficiency, reduced lead times, and lower production costs.

Furthermore, machine learning algorithms can revolutionize supply chain management in manufacturing. Supply chain management involves coordinating the flow of materials, information, and finances across the entire value chain. Machine learning algorithms can analyze vast amounts of data, including sales forecasts, inventory levels, transportation schedules, and supplier performance to optimize supply chain operations. By accurately predicting demand, these algorithms can optimize inventory levels, reducing excess inventory or stock-outs. Additionally, machine learning algorithms can optimize transportation routes and schedules, enabling just-in-time delivery and minimizing transportation costs. These improvements in supply chain management not only enhance manufacturing efficiency but also result in improved customer service and reduced costs throughout the supply chain.

In conclusion, machine learning algorithms offer a game-changing solution for enhancing manufacturing efficiency. By applying these algorithms to areas such as predictive maintenance, quality control, production planning, and supply chain management, manufacturers can improve their operations and achieve significant cost savings. The benefits of machine learning algorithms include proactive and efficient maintenance, improved product quality, optimized production planning, and streamlined supply chain operations. As machine learning technology continues to evolve, it is expected to play an increasingly crucial role in revolutionizing the manufacturing industry, driving growth, and competitiveness.